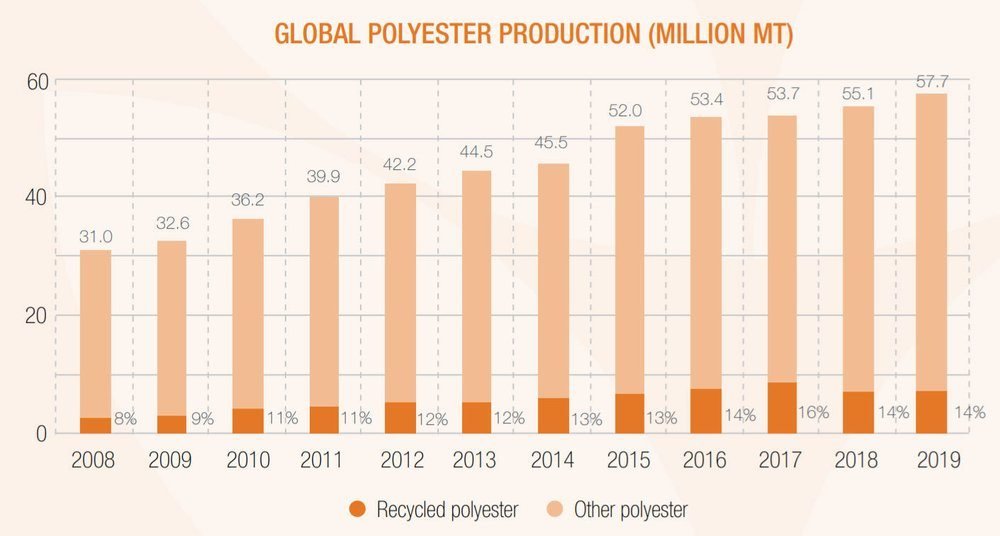

Recycled plastics are playing an increasingly important role in the textile-clothing industry. In which polyester weighed 52.2% of materials used in 2019, far ahead of cotton (23.3%). That same year, 14% of the 57.7 million megatons of polyester used, were recycled polyester. Nevertheless, sorting is still the essential preamble to any attempt to recycle plastics, which are being thrown away in increasing quantities in our garbage cans. This poses new technical challenges for the sorting sector.

“If we want to recycle more, we need to refine the sorting process, which is out of all proportion to what we used to do,” says Antoine Robichon, deputy director of Citeo, the eco-organization in charge of household waste.

In France, the public authorities reminded on Tuesday the objective to reach 100% recycling of single-use plastics by 2025. But only 27% of plastic packaging is currently recycled, according to the Ministry of Ecological Transition. The rate rises to 61% for the bottles and flasks.

The extension of sorting instructions continues: half of the population is now concerned and it will be all in principle by the end of 2022, or 100 billion packages each year sorted by 30 million households. But “for new recycling technologies, especially chemical ones, we need a fairly high quality” of the material given to recyclers, explains Mr. Robichon. The sorting centers must meet the specifications of recyclers who want plastics well sorted by resin type and without impurities (no food scraps or other materials). Citeo has therefore decided to launch sorting centers specifically dedicated to “over-sorting”, the first of which should be “operational in 2023”, says Eric Fromont, Director of Collection and Sorting Projects at Citeo.

AI and continuous monitoring

The use of artificial intelligence (AI) is one of the innovations selected in February by Citeo. For example, the OMNI project, led by Valorplast in partnership with Total and the start-up Recyclye, uses artificial intelligence to identify food and non-food plastics, a key element in sorting to optimize the circular recycling of these products.

Another project, Qualixo, by the start-up Lixo, aims to measure the quality of sorting continuously on the sorting line, from the entry of the collected batches to the composition at the exit, whereas the control is usually done by samples. The system allows, with a small camera, to characterize the different types of plastics by their shape. The images are continuously processed, feeding recognition algorithms, and data on the composition of the waste stream is sent to operators.

“Image recognition sorting is relevant, but it won’t replace 100% of the machines in the sorting centers,” acknowledges Marjorie Darcet, Lixo’s general manager. But several sorting centers are already installing it and a version is being tested directly on waste collection trucks to analyze their contents before the sorting center.

Continuous quality control at the exit of the sorting center thanks to AI is also at the center of the Autodiag project led by Suez. “Equipment suppliers will improve their detection programs each time there is new packaging” put on the market, but “the citizen’s actions are very important” at the beginning to prepare the waste collection, underlines Alban Cotard, expert in plastic recycling at Valorplast.

See the full article on Fashion Network